Supporting Safety

Sustaining Standards

Influencing Transformations

Products We Carry

We are the official dealers for world-class fabrications, parts and machinery for your EPC needs.

An air separation plant separates atmospheric air into its primary components, typically nitrogen and oxygen, and sometimes also argon and other rare inert gases.

The most common method for air separation is fractional distillation. Cryogenic air separation units (ASUs) are built to provide nitrogen or oxygen and often co-produce argon. Other methods such as membrane, pressure swing adsorption (PSA) and vacuum pressure swing adsorption (VPSA) are commercially used to separate a single component from ordinary air.

Having years of experience in the gas industry, we collaborate only with well known brands and using the latest air separation technology available. HangYang (HangZhou) and SASPG Sichuan Engineering Co., Ltd. (Engineering Plate).

Liquefaction of natural gas plays crucial role in the industry. Natural gas is converted to a liquid in a liquefaction plant, or “Train”. An LNG Train performs four main processes: 1) Pretreatment. Remove dust and slug (water and condensate) along with hydrogen sulfide (H2S) and mercury (Hg). Here at Arohera, we offer a compact, reliable and energy efficient liquefaction plant.

By making partnerships with well known brand in the industry, we have successfully completed liquefaction plant projects within scope of EPC and maintenance.

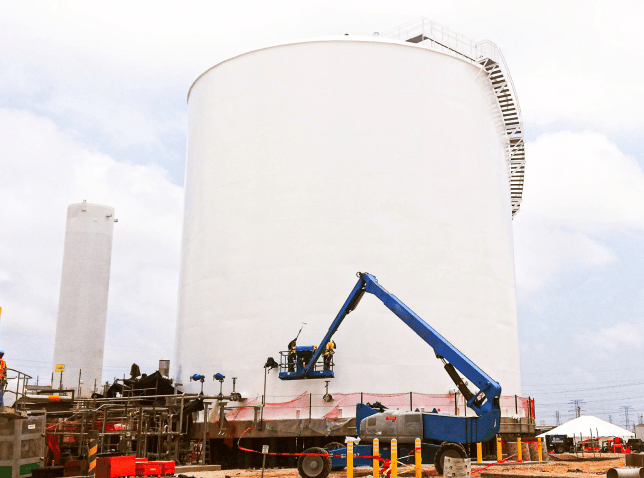

A liquefied natural gas storage tank or LNG storage tank is a specialized type of storage tank used for the storage of Liquefied Natural Gas. LNG storage tanks can be found in ground, above ground or in LNG carriers.

LNG storage tanks have double containers, where the inner contains LNG and the outer container contains insulation materials.

We have wide range of cryogenic storage tanks and solutions delivering proven reliability, reduced maintenance, and lowest cost of ownership for the full spectrum of liquefied gases.

We have built a reputation for excellence in erecting Flat Bottom Tanks. With decades of experience in the industry, PT. Arohera has become one of the pioneers in LNG Storage Tank construction in Indonesia, earning a well-deserved reputation for their expertise and high-quality work.

Over the years, PT. Arohera has completed numerous projects, and their portfolio of work speaks volumes about their capabilities.

Our principal manufactures a comprehensive range of vaporizers for the industrial gas, LNG and petrochemical industries. Our Vaporizer line includes a wide range of products such as: Ambient, Electric, Water Bath, Shell and Tube and well service Vaporizers.

Years of experience in the industry enable us to provide a premium solution for our customers.

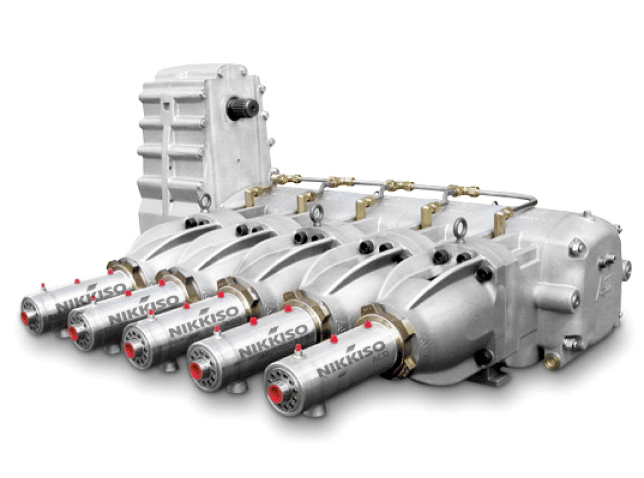

Our cryogenic pumps span the entire range of needs, from small to large Cryogenic submerged motor pumps, and everything in between.

With our combined resources, we are further developing our comprehensive LNG value chain and offering centrifugal and reciprocating pumps, vary in sizes, small to large.

Vacuum Insulated Pipe is a key component to deliver the optimum turnkey cryogenic solution for various liquid gas applications.

The design and layout of each vacuum jacketed piping system is specific to the installation. The VJ piping is provided in vacuum sealed sections which are typically connected by cryogenic bayonets to form a continuous piping system that is uniform and efficient. This technique of utilizing cryogenic bayonets allows for ease of installation and overall system integrity.

Our principal provides high quality tubes from various materials: Carbon steel , Stainless Steel, nickel alloy and special alloy, and used in a wide variety of industries including petrochemicals, refining, power gen, and oil and gas among others.

As a leading manufacturer of finned tubes, our principal has the facility to produce and supply finned tubes to suit all applications. This would eventually allowing us to serve you better.

PSA (Pressure Swing Adsorption) compresses everything, while (Vacuum Pressure Swing Absorption) VPSA compresses the oxygen only. VPSA systems are less susceptible to humid environments compared to PSA systems due to the robust design of the adsorption column. VPSA uses an oil-free blower, thus avoiding any oil carryover common with oil-lubricated compressors.

Our principal products can be used in a wide range of applications within many different sectors such as: aquaculture, ozone and water treatment, medical oxygen applications, mining and mineral processing, military and field hospitals, modified atmosphere packaging and more.